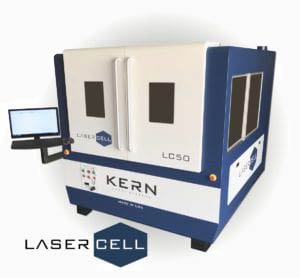

Kern LaserCell Machine

A fully enclosed (Class 1) design allows the LaserCELL to be placed in high-traffic areas such as busy factory floors and university classrooms. Access points are available at the front, back and sides of the machine making part loading/unloading and maintenance simple and convenient.

The LaserCELL debuts Kern’s next generation HyperDual motion system. This redesigned motion package has transformed the LaserCELL into Kern’s fastest and most productive machine to date. Lasers from 50 to 400 watts can be placed onto the LaserCELL platform.

The Pipe Rotary, K-Vision Camera Registration and Metal Cutting options are all compatible with the LaserCELL equipment.

Beam Delivery

A LaserMech FiberMini® beam delivery is installed on each FiberCELL system. The FiberMini features an easy to install cover lens which protects the focusing lens. The entire beam delivery is sealed and purged with positive gas to keep out dust and other particles.

HyperDual Motion

The HyperDual system features a dual servo motor/rack and pinion design resulting in greatly improved speed and acceleration. The accuracy and repeatability of the FiberCELL’s motion system well exceeds the demands of Kern’s growing customer base.

Safety Enclosure

The FiberCELL is equipped standard as a Class I, fully enclosed laser system. All doors and access points are interlocked ensuring a safe working environment. Special polycarbonate windows protect users from potentially harmful laser wavelengths.

Computer Package

A high performance computer, with Windows OS, is supplied with each FiberCELL machine. The computer is connected to the laser via Kern’s USB DSP technology and KCAM Laser Software. Nesting, common-line cutting, lead-ins and tabs are an easy task with SigmaNest® Techno™ Software.

Front/Side Access

The FiberCELL features dual sliding doors at both ends of the laser system. Sliding access windows are also installed on both sides of the machine. The variety of access points ensures operators are able to access all areas of the table with ease.

Programmable Gas

Up to three gas supplies can be hooked up and utilized simultaneously. For example, pierce stainless steel quickly with oxygen, then switch over to a nitrogen assist gas for the cut profile giving you a shiny edge quality and dross free cut.

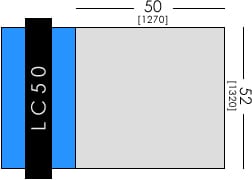

Work Areas

Laser Wattages

Standard Features

- High Performance Computer & LCD Monitor

- Closed Loop Chiller (100W and greater)

- Exhaust Blowers / Downdraft Vacuum Bed

- HyperDual Servo Motion Package

- 2.5″ S-Focus Optics Assembly

- KCAM Laser Software

- CorelDRAW

- 2 Days Training at Kern Facility

- Laser Safety Kit

- Laser Tool Kit

Optional Features

- Metal Cutting Option

- K-Vision Camera Registration

- Rotary Device

- Aluminum Spacers

- 1.5″, 5″ & 7.5″FL Optics Assemblies

- PhotoGRAV Software

- On-Site Installation & Training

- Fume Extraction Unit